Old processes weren’t static — they changed, often rapidly. I say old, but they weren’t old then, they were new; at their early stage. That is the stage when much of the work was being done without big industrial support. It so happens, that is the point we get to after the process has been abandoned by its industrial supporters. We go back to the mechanical age of photography.

The loss of dye transfer matrix film is the obvious gap to cross; however, the bigger loss, partly since it is little discussed, is the mordanted paper. It wasn’t just glossy, it was very smooth gloss with multiple coatings of mordanting. This is the high reflection density giving a Dye Transfer its look of saturation. The dyes were never special, really, not that pure; the yellow being very impure. This, in part, explains the “red” of Eggleston’s prints.

Process is a life-style thing at the beginning, and at the ending. The Cycle of ….

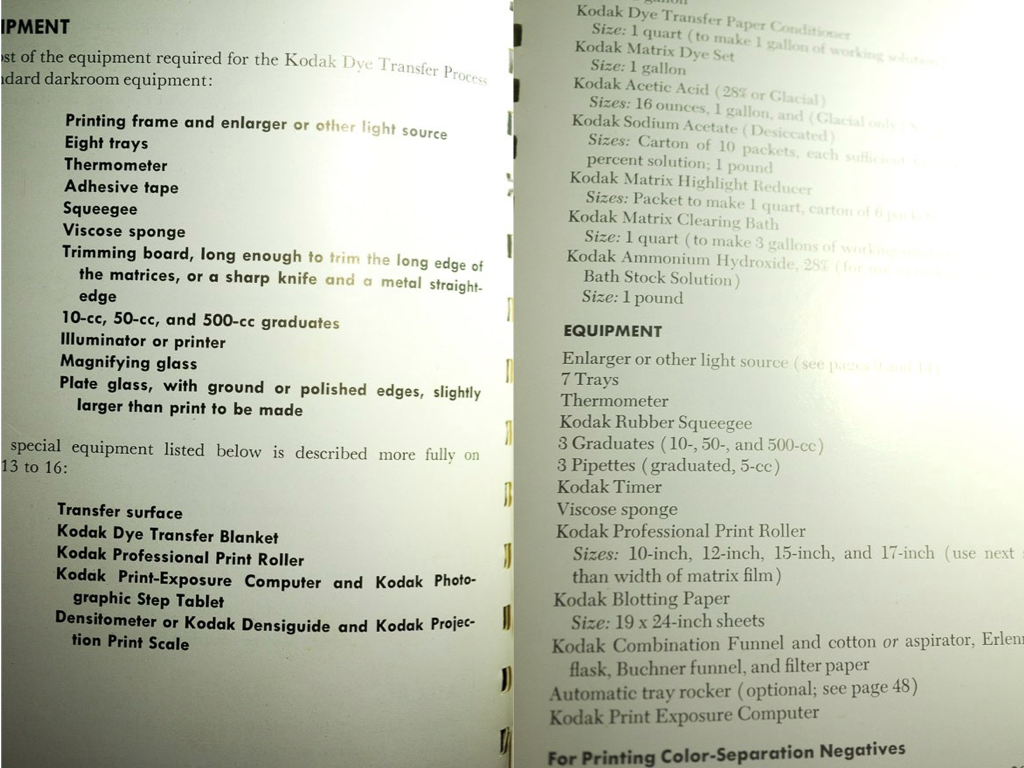

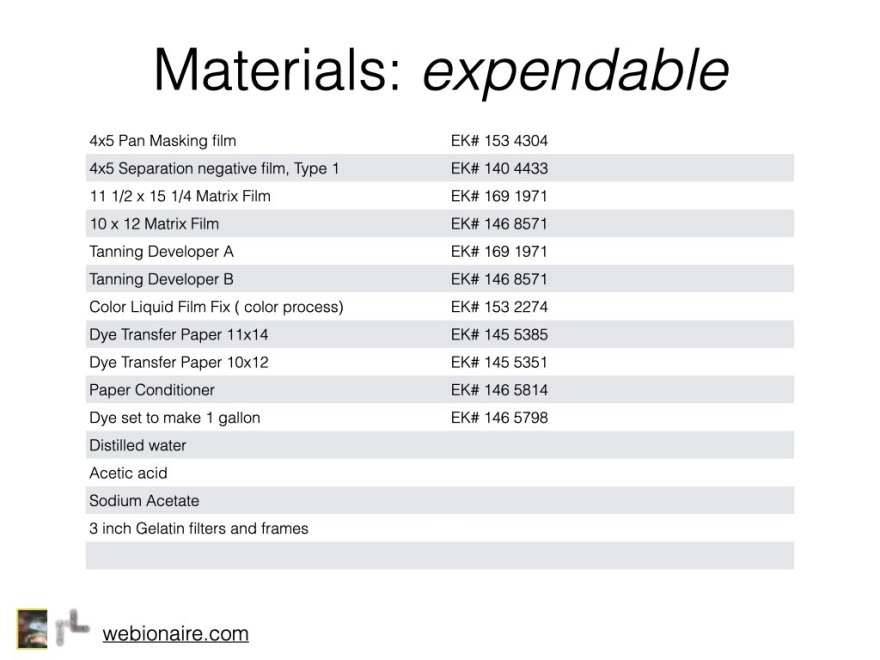

The equipment needed listing from two different issues of the Kodak Dye Transfer guide. These are from the 50s, as the process went from a maybe to the main way of printing from color. Dye Transfer rapidly replaced Carbro, becoming the preferred way for print publishing — advertising, in fact all media.

By the time Dye Transfer entered the 60s, Kodak had already introduced its replacement: Type C, the process now called RA-4, after the chemistry used. Fujifilm and Kodak have color paper for the process. The process of printing color this century doesn’t involve anywhere near the amount of supplies of last century.

These days: No Assembly Required. Unbox. Mix. Print.

You must be logged in to post a comment.