Color photography is a negative positive process (mostly). What is dark in one, is light in the other. What is red in one, is cyan in the other. The type-C, chromogenic, prints used to be made from “keyed,” or matched negatives and positives, with each emulsion maker providing paper for printing their negative film. That was during the height of the film-age, now, we have negative stock made by one company, with paper being made by a different company. [ 12/23. perhaps Harman Technology will change this. To survive, they have entered the color film world. Making a paper is easier than making a film]

Commercial, hand print labs often said they were engaged in hand-to-hand work. The first pack out of a box was termed the Zero Print. That print would then be used to determine the center position of a ring around test. These were done in the custom lab, or section of a larger 3 shift lab.

The machine prints, were made on an optical printer. The term optical has become a marker among the amateur as a high point of craft. It wasn’t back then. We also called those machines “hotheads” and the stand alone labs using them were called “crab shacks” since they were located in food courts, until their smell moved them outside, or down the back halls of the mall. Kodak marketing material picked-up the word “optical” from their Hollywood print labs, and moved it into literature. This was a distinguishing term from the digital intermediate print.

Enlarger prints were initially called “projection,” then “aerial,” until the time when they were named after their machine. An enlarger, or an optical printer.

SOME BACKGROUND: Printing color negatives. The negative is part of a system designed to solve the problems of making color prints using photographic means. Since motion picture industry was familiar and capable of producing many prints repeatably, the Agfa scientists produced a subtractive color print process suited to 35mm processing. In 1939, a century after the discovery by Daguerre, Agfacolor negative film was produced in conjunction with their positive film. The negative film was for the camera, the positive film was for projection. This is the same conceptual mode of ECN, Eastman Color Negative of Kodak. The positive film is called an ‘intermediate’. These are chromogenic (make dye) not chromolytic (dye destruction, dye bleach)

1932. First 3-color Technicolor film introduced

1935. Kodachrome film introduced as 16mm amateur color film

1939. Agfa introduces Agfacolor.

1941 Type I Kodacolor paper, used CD-2 developing agent

1951 Type III Kodacolor paper, used CD-2 developing agent new m

1954 Type 1348 Kodacolor paper, used CD-2 developing agent

1959 Type 1502, used CD-3 developing agent and new c and y

1961 Type 1583 new UV absorber

1963 Ektacolor 20 Type 1852 new m and y

1965 Ektacolor 20 Type 1870 new m stabilizing agent RC and FB

1970 Ektacolor 30, 37, no cadmium, mercury, new m and y, RC

Professional papers

1946 Type III Ektacolor paper, used CD-2 developing agent

1954 Type “C” Ektacolor paper, used CD-3 developing agent, new m and y

1961 Ektacolor Professional paper, new c, m and y

1963 Ektacolor Professional paper with Type II stabilizer in Ektaprint C

1970 Ektacolor 30, 37 merge chemistry

1942. US2360225A This invention relates to photographic masking such as that used for color correction

1944. US2449966A. The answer to masking color negatives. Integral mask for color film. Wesley T. Hanson. Why masks are orange — exactly why.

- Subtractive Color Photography: Spectral Sensitivities and Masks* W. T. Hanson and W. L. Brewer J. Opt. Soc. Am. 45(6) 476-481 (1955)

- Subtractive Color Reproduction. The Approximate Reproduction of Selected Colors* W. L. Brewer, W. T. Hanson, and C. A. Horton J. Opt. Soc. Am. 39(11) 924-927 (1949)

- The Theory of Subtractive Color PhotographyI. The Conditions for Perfect Color Rendering* J. A. C. Yule J. Opt. Soc. Am. 28(11) 419-430 (1938)

- for a list of emulsion making patents see: portra

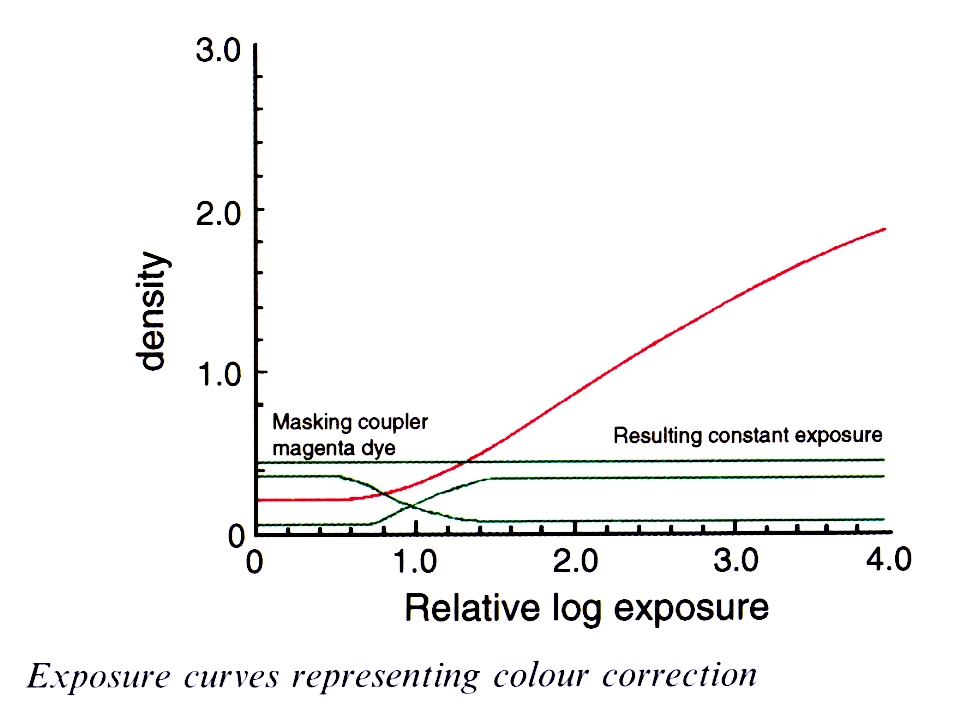

The Orange color is a colored coupler, a “masking coupler.” The orange is these colored dyes that have not reacted with oxidized color developer; the orange is a mixture of these dyes. The two common masking couplers are a yellow colored magenta dye forming coupler, and a magenta colored cyan dye forming coupler. These are coupling-off group and is responsible for the initial color. This group has no ballast and should wash into the processing solutions. Selection of these dyes requires that this washing out will not cause dye stain. They are selected so that they will react with processing chemistry (C-41), producing colorless bi-products. Most aniline capable of forming diazonium salt can be reacted with many couplers to produce a wide range of masking couplers.

The Practical:

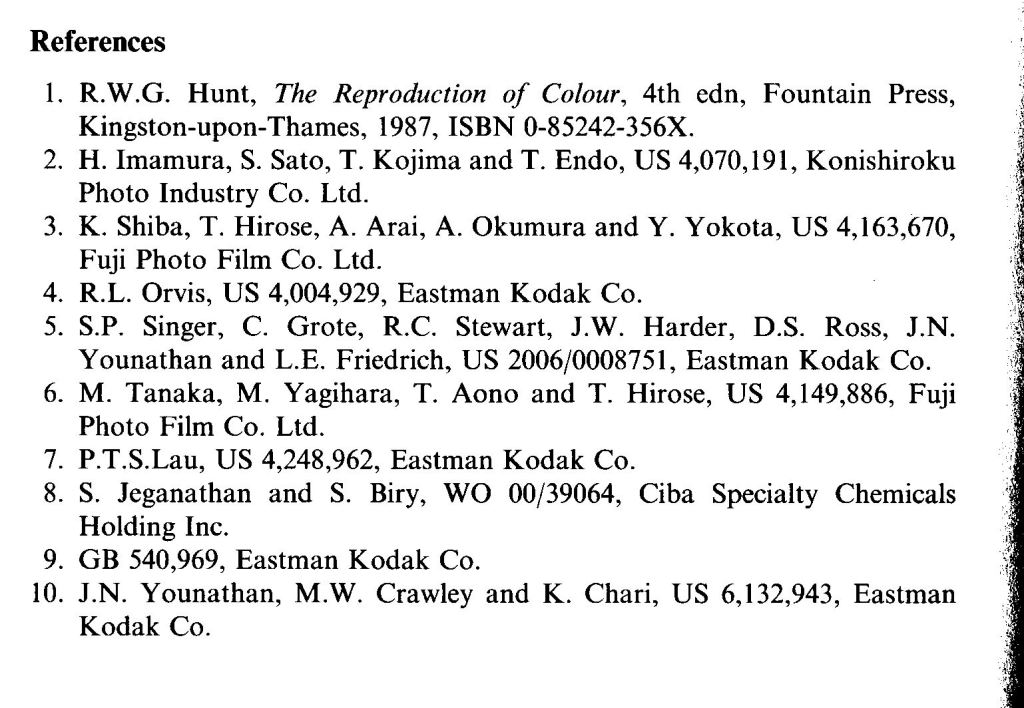

Photography is an illusion: an acceptable approximation. In its original chemical form, it was

lossy

reduces without possibility of restoration. Distinguished from lossless: data is not lost upon compression or transfer.

in this “compression” the expansion is not recoverable. The first development step reduces the amount of data. We change the spacing — expanding or contracting. We cannot recover what is discarded in the preceding step, not without retouching.

The color negative is the first part of a two step process. Its design is made assuming the light of first exposure, as well as the light of the printing step — the exposure of the print material.

- camera light: commonly daylight

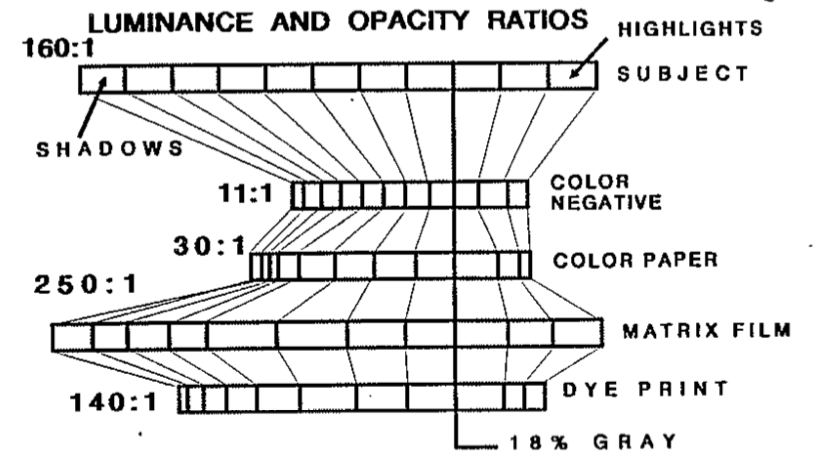

- printing light: tungsten was the original design “standard light.” 3200K / 3000K — both were described and used in labs. The original enlargers were built using the PH2* lamps. This was the match used for Type C prints. The recommended filter packs were built to print the “orange” mask and this color lamp at reasonable middle values of Magenta and Yellow CP (color printing filters). CP was not optical quality, CC, color correction filters are.

- viewing light: printshop standard was introduced by MacBeth Co. It is: 5000K. 90+ CRI. Intensity of 1400 + or – 300 candles per sq. meter.

Reference material for the first time printer —

THIS PAGE WILL BE BACKFILLED. Under consideration is a pdf with current printing methods including contrast and color masking.

what is the difference between professional and amateur films? SEE

mantra: a filter passes its color as it blocks the others. A red filter passes red light as it blocks green and blue light.

Where is the orange?

Consider this experiment:

- process an unexposed piece of Color Negative (CN)film. full C-41 steps.

- using another unexposed piece of CN, skip the development step of C-41. it goes only through Fix Bleach (or, Blix)

- yet another piece of unexposed piece of CN, take this through a BW developer process, such as D-76

- for a 4th test, process an unexposed, undeveloped CN film in a BW fixer, such as Hypam. Does it look like any of the prior tests?

- And Finally, using the piece of film from #1 and #3, strip/ bleach the emulsion from the film. Chlorox, a chlorine bleach. The will now be without subbing, down to the conductive material and support plastic only.

What are the color changes you see; are there any. Where is the Orange; when is it “darkest”

| Film | Magenta | Yellow | Exposure |

| F 400H | 80 | 75 | 7.5 sec 11 1/3 |

| Ektar 100 | 75 | 65 | 7 sec 11 1/2 |

| Portra 160 | 85 | 65 | 7 sec 11 1/2 |

Why did they start at so much red(M+Y). The first enlargers had PH lamps, a red burning lamp. Equally important, cyan filters are poor adherents to the pass my color rule. Increasing cyan density on an enlarger counters the PH lamp quickly, concurrently with greater density, a practical cyan filter has greater variance from being cyan and only cyan.

WESLEY T. HANSON, JR.

Sept. 21, 1948. w. T. HANSON, JR

2,449,966

INTEGRAL MASK FOR COLOR FILM

Correction of the colors on printing is therefore desirable, and this is usually done by masking, as described in prior patents, such as Evans Patent 2,203,653, granted June 4, 1940, and my prior Patent 2,294,981, granted September 8, 1942.

Evans U. 8. Patent 2,203,653, referred to above describes a method for making an integral mask in a multi-layer reversal material, but the mask is black or gray in color and does not secure the advantages of colored masks such as described in Evans U. 8. application Serial No. 413,442, filed October 3, 1941, now U. S. Patent 2,376,132, granted May 15, 1945.

which a, color coupler is incorporated in the sensitive emulsion layer prior to exposure. Processes of this type are described, in Mannes and Godowslay Patent 2,304,940, granted December 15, 1942, and Jelley and Vittum U. 8. Patent 2,322,027,

granted June 15, 1943. These processes are particularly useful as negative-positive processes

producing such dyes are described in numerous prior patents such as Marines et al. U. S. Patents 2,039,730, granted May 5, 1936, 2,108,602, granted February 5, 1938, and 2,115,394, granted April 26, 1938. In Figure 1 it is assumed that the relative concentrations of the dyes are adjusted so that when layers containing the three dyes are superposed, a neutral gray image is produced.

Patent 2,304,940 or the Jelley and Vittum U. 8. Patent 2,322,027, referred to above. The coupler need not be incorporated in a. waterpermeable, water-insoluble solvent as described in those patents but may be incorporated in insoluble or non-difiusing form in the emulsion. The

coupler is colored so that it absorbs light prior to coupling but upon coupling is converted to a form which absorbs the color desired for the final dye image. The color of the original coupler is chosen so that it absorbs light of the same color as the undesired absorption of the dye formed from it. In this way, the colored coupler can correct for the improper absorption of the coupled dyes and thus effect complete masking. Depending upon the correction desired, the cyan coupler should be red, orange or yellow, the magenta coupler yellow or green and the yellow coupler magenta or blue.

Cited: Michaelis 2193931(silver dye bleach), 241413,

Schultze 2307162 ( dye bleach)

later patents citing this base work 2241413

GB503824A * 1936-07-07 1939-04-11 Kodak Ltd Process of colour photography

US2193931A * 1936-03-24 1940-03-19 Bela Gaspar Process for producing multicolored photographic images

US2241413A * 1937-03-23 1941-05-13 Chromogen Inc Photographic printing process and image for use therein

US2307162A * 1939-06-06 1943-01-05 Gen Aniline & Film Corp Process for the production of color images

You must be logged in to post a comment.