The digital RA-4 paper notes. Endura in 2013 included printing in darkroom. 2019, no such advise. See the calibration routines for setting your digital printer. I don’t know that any of these papers are sold in 2023. The world, especially in non-western countries, is rapidly moving from wet-lab to dry-lab imaging.

The “analog resurgence” is a thing in major metropolitan areas, but a thing for 35mm film. Along with this bounce has come a demand for scanning; a demand so strong that premiums are being paid for scavenged “scan heads” of minilab equipment.

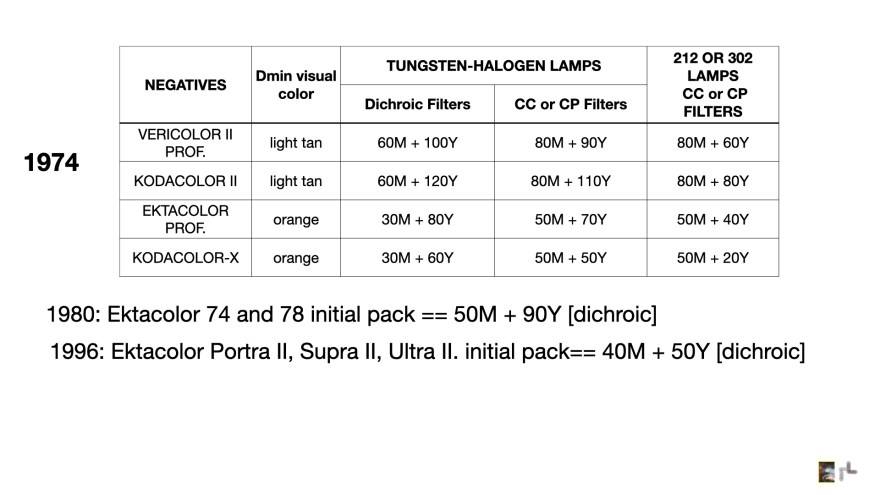

Of note should be the filtration recommended for Kodak Endura Premier paper. A white-light starting pack of 40M+50Y, or a Tricolor filter set of 25,99,47B … Don’t forget — still recommended are IR and UV filters (B).

From the datasheets you could build upon your Rosetta of process procedures.

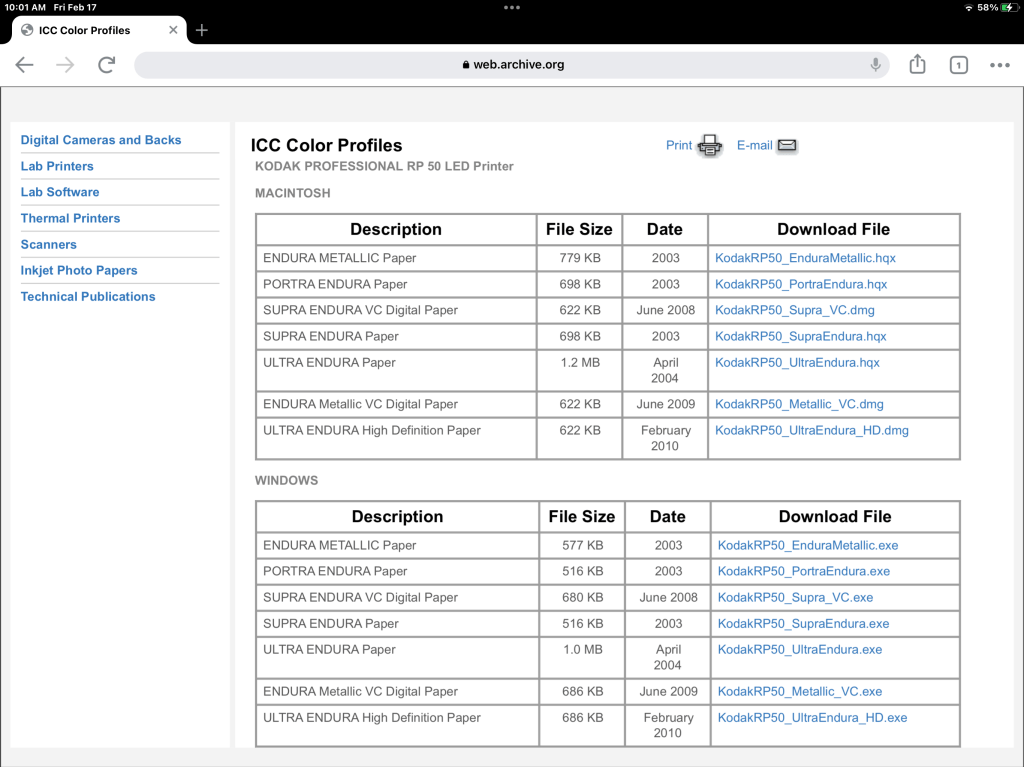

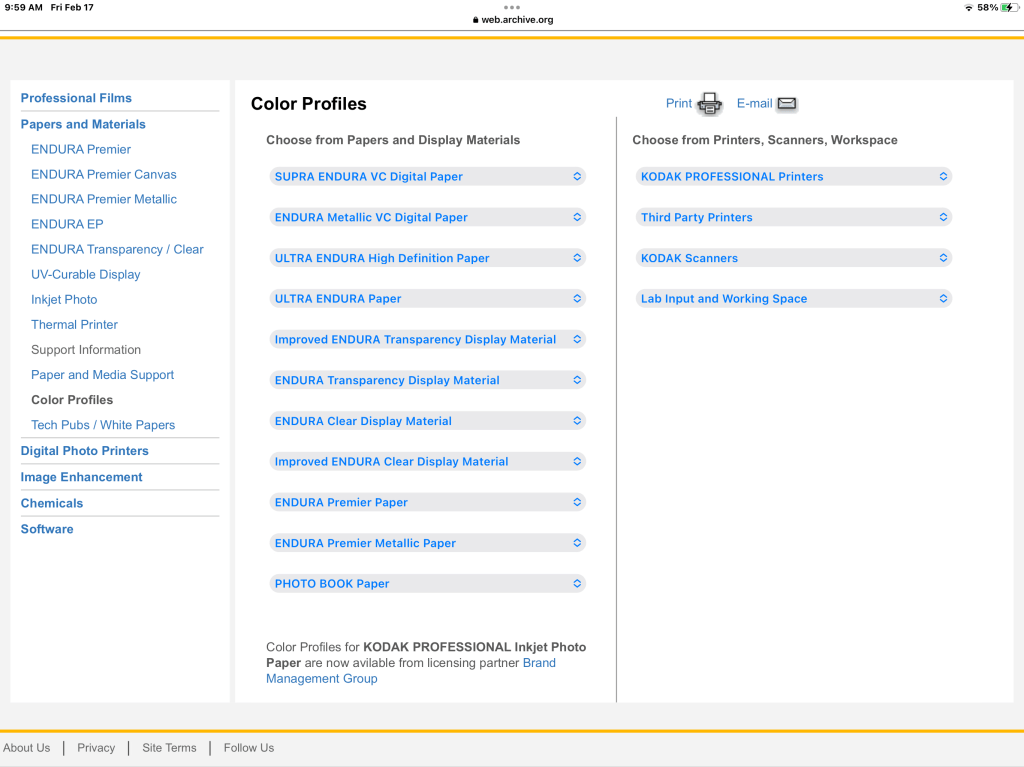

Profiles provided by Kodak give you an indication of what products have been made, but not what is current product.

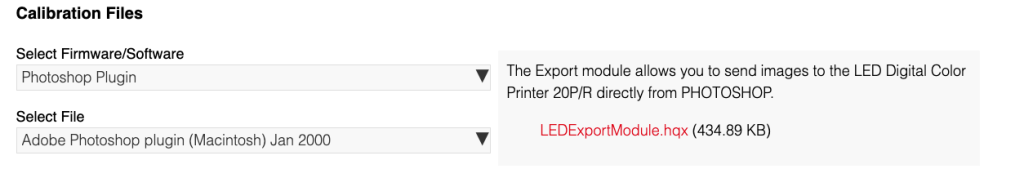

Kodak’s LED Digital Color Printer model 20O/R can be controlled from within Photoshop. Yes, Kodak made LED printers, no matter what the Forgotten of Foradum say. It also suggests that calibration of LED printer is possible for at least one Kodak RA-4 paper.

Of course, ZBE’s Chromira is a long standing LED printer used by many US West-Coast labs.

http://www.zbe.com/usergroups/files/products/chromiraprolab/manual/ChromiraProLabUsersGuide_v1.pdf

You must be logged in to post a comment.