was it a key. who knows who knows what they know.

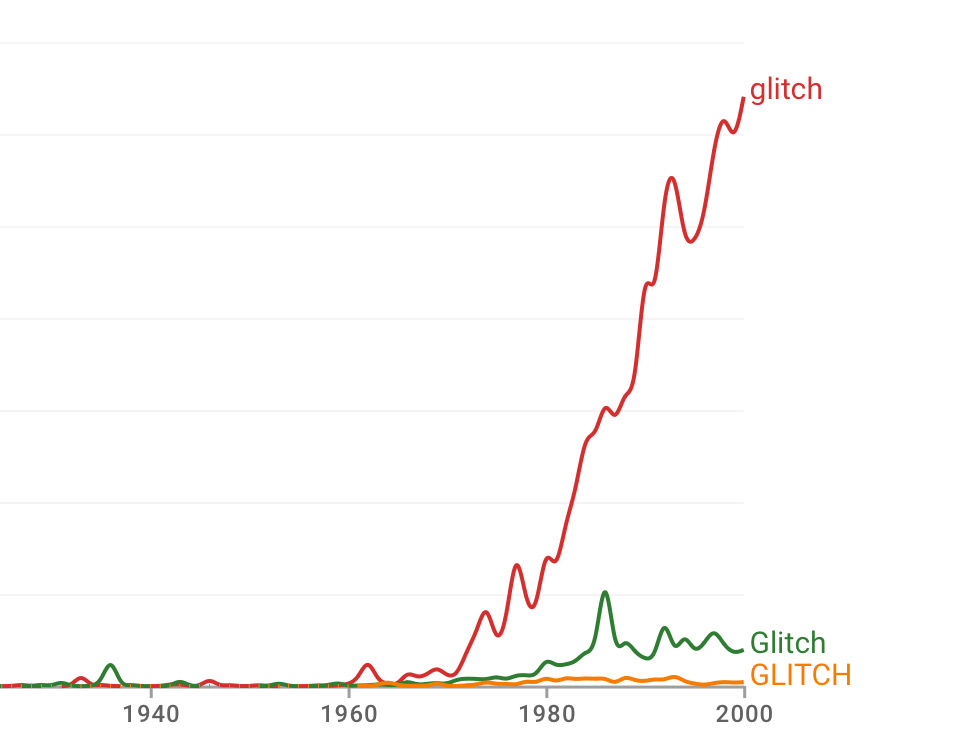

HC-110 entered the stream as an addition to dye transfer printing. My view. It appeared in literature distributed to the avid darkroom “enthusiast.” — what we called the Dentist Darkroom. Over time, Kodak taught the duo Super-XX and HC-110 to the weekenders and small, part-time printers. The reputation grew thru repetition. This century, with a sense of failing industry, HC-110 held onto its claim of mystic value by being difficult to make, hence, it would be a catastrophe for it to disappear. The value of association plays background to this.

Dye transfer, large shops, had multiple lines. The small ones could use HC-110; however, the large, deep lines would never be taken over by HC-110, so, DK-50 remained.

Enter the gossip track…

IN A SLIP OF THE LIE, HE TOLD THE TRUTH.

Back to HC-110 original style. MSDS sheets aren’t required to list every ingredient, just hazardous ones, and with trace or trade secret ingredients exempt from being listed. I know someone who didn’t formulate a personal batch; but he had access to a major research lab, and the right background to do it. It was tricky. Certain ingredients aren’t ordinarily available.]] photrio. He probably meant to say he knows someone who DID make it. The reason he makes the claim is to bolster his standing among those of little standing.

final state of ausi — info being sent to chemists.

Of course, all this work was for the Old HC, the syrup, not the current HC-110.

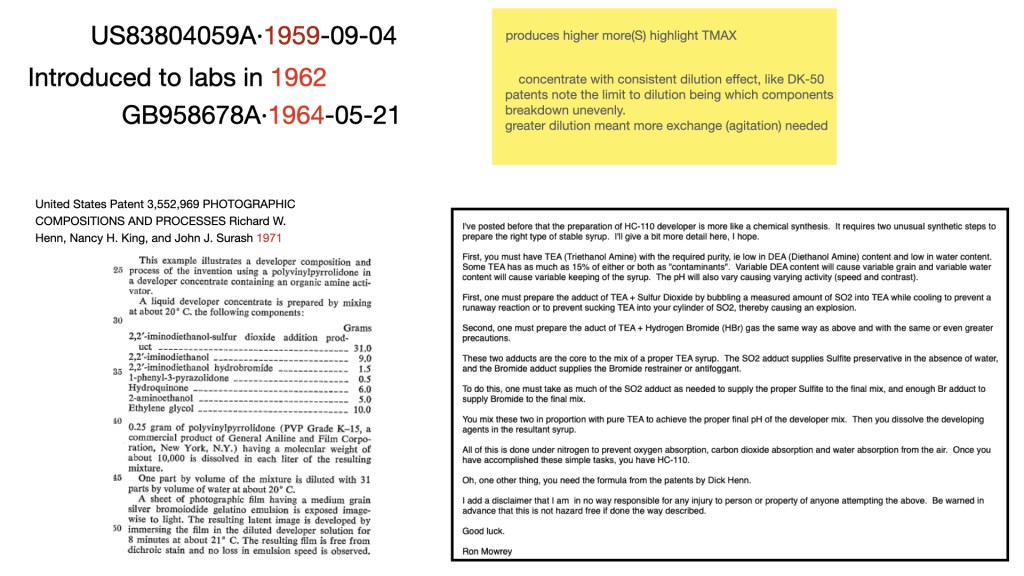

The patents tell more. The 1959 patent is about concentrated developers. The motive is for reduced storage space, faster mixing as well as modifying gammas of film without resorting to multiple developers. The 1964 patent provides information about dilution effects. Dilution reaches a limit, which is why Kodak listed the few dilutions they did. Patents do tell a story to those familiar with reading them.

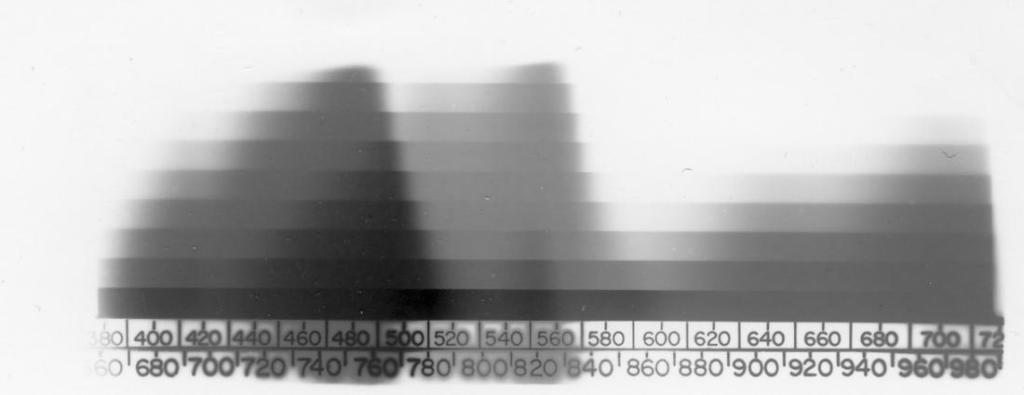

I used HC-110 after using DK-50. I began making masks and seps with DK-50 — after the HC syrup disappeared, I returned to DK-50. My lab films are Ilford: Delta, PanF+, FP4+, and Ortho Plus. These films provide what is needed to make masks and separations for color and BW procedures.

Avoid the forums (my recurring theme) — use manufacturers first; then check with old texts. Use google books. Most important: try things, keep notes. Be certain to follow the information of those who have done more than repeat overheard counter-talk.

Once the syrup hit the water, its main purpose is lost. Once the syrup left the manufacturing, the major value of those researchers was lost.

Characterizing film+developer combination isn’t as time consuming as re-formulating a compounded chemical like HC-110. Falling back to DK-50 from HC-110 is a few hours effort, not days, certainly not the months expended trying (and failing) to compound the Aussie HC-110.

You must be logged in to post a comment.