a reminder of color separations: what they are; what they do.

A separation is a pulling apart — taking either the scene, or its first duplicate into distinct parts. The separation is based upon the color. These being the primary colors of tri-color theory.

Film wasn’t always on ESTAR, so small holes would fail; they weren’t done. The stable base was glass — not punchable. We had methods, just not punch-pin positioning systems.

Masking can be done pre or post separation. // more to come//

craft skill from the book of Reproductions. These were from ‘inkside’ of the past, along with the current vantagepoint. The titles and the dog-tags for return reading.

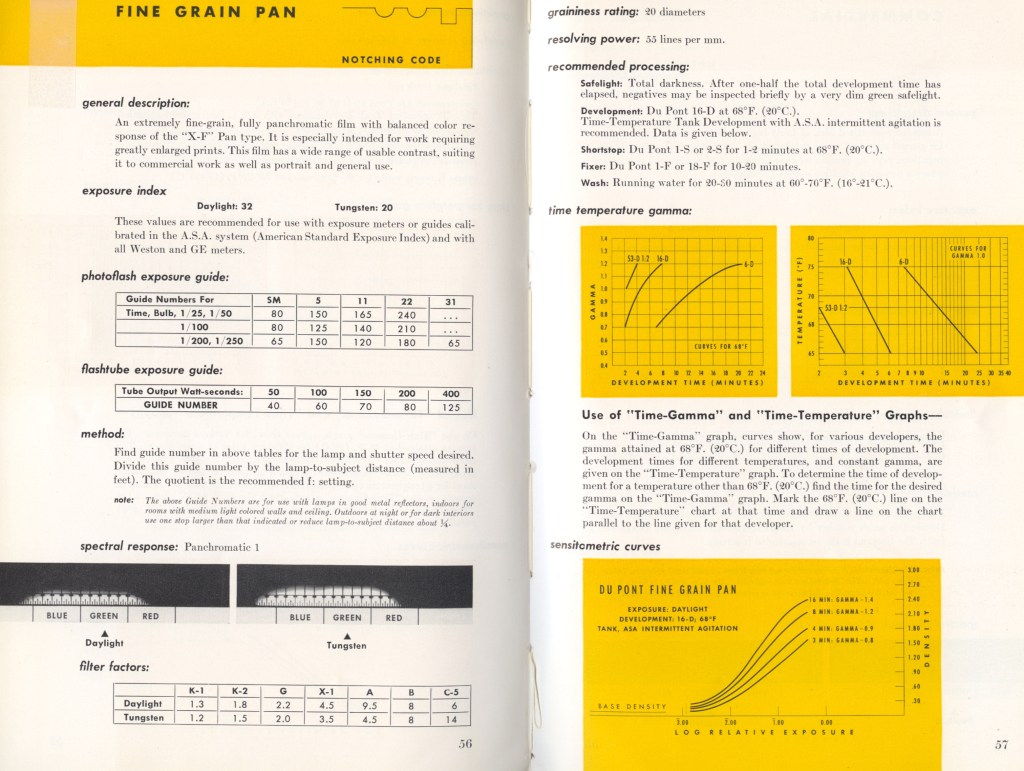

Choosing film is premised upon several factors, notably, color response and curve dynamics. Can the separation match the transparency? Can the film render the colors in the transparency as monochromatic approximates. Much, too much, is said about “long straight line” needs of separation and mask films. What you are separating from rarely has as long a linear portion as most BW films; not now, and certainly not in the past when seps were the king of the darkroom.

From the past; more for the Rosetta stone. Translating data sheets. Why that film/developer was made.

Dupont Fine Grain Pan: an easy 20x intermediate film. Soup in 6-D or 53-D.

Why Dupont 16D developer: times of 6,7,8,9 minutes gave those gammas (close enough to get you started on separations using Dupont films.

from 2005: Modern vs. Classic. Thin vs. Thick Emulsions’

Early form of specialized equipment designed to make separation negatives.

It looks quite “steam punk” in this light. Hardly the item of extreme, near sacred skill-tool of conversation on today’s net world. The virtual barstool has a way of inflating all needs beyond the original.

Making the process sound complex has a purpose: make the teller important.

Balanced pan-chromatism — the secret word on separation negative film.

not Filter Factor, rather Exposure Ratio. Notice the difference in using Heat Absorbing Glass — IR glass was as important as voltage stabilization in the best custom labs. The “4 shift” places all knew this. Not now. The forums think the glass is so negatives don’t pop — change during exposure.

IR and UV affect emulsions… even just a bit. The amount makes significant difference when making seps with a responsive emulsion.

| Emulsion Type | Red Negative | Green Negative | Blue Negative |

|---|---|---|---|

| Panchromatic | Use Red filter | Use Green filter | Use Blue filter |

| Ortho-chromatic | Unsuitable. insensitive to red | Use minus-blue or green filter | use minus-green or blue filter |

| Ordinary (non-color | Unsuitable. insensitive to red | Unsuitable. insensitive to green | No filter needed. UV or minus-green or blue filter. |

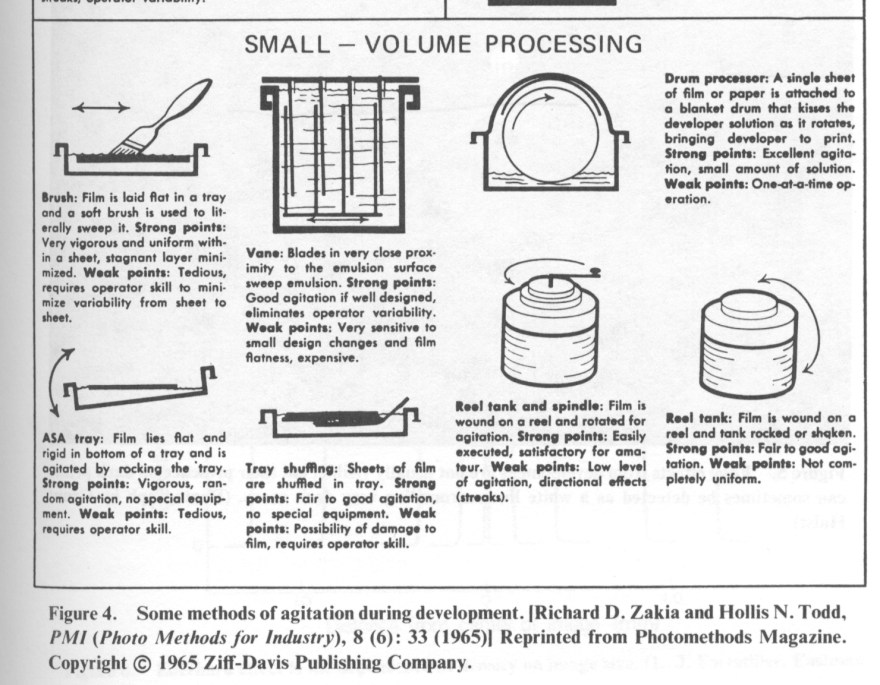

The above table was often used as a test of new employees … did they understand the theory enough to make separations using the “wrong” film or developer. Failure meant not trying. Understanding development scheme on curve shape was a key skill among the proficient lab tech. Use fresh developer. Use consistent agitation, including the rhythm. Blue sep toe usually reaches higher density than the red and green seps. Use this during your density limits, your aims, for the linear portion of your characteristic. In practice, that is part of why we set low limit above 0.40, with 0.30 being the lowest safe value for a separation set.

Adage: Mix for Four. Use Three. — meaning: put only 3 sheets through chemistry that should work for 4 sheets of film.

You must be logged in to post a comment.