Kwik-Print is another process you can’t do — the materials are not available. Unlike dye-imbibition, there aren’t enough records to devise the same product. The general procedures can certainly be re-issued. It was a simplified gum-pigment process, even though it was not gum arabic based. KP was an assembly process used by commercial printers as a proofing system. As such it found ready home for use within schools teaching any of the assembly processes.

NB: if you would like me to post a page2 with directions, push the like. With enough interest shown, it will happen

It was part of the Peak Know-How of 1978. Kwi-Print providing early access to color making for those who can’t draw and otherwise avoid painting. Kwik-Print was an assembly process; in that regard it was similar to dye-transfer, as were several hundred color making processes in the earliest years of photography-mechanical processes. Reviewers likened it to the Fresson Quadirchromie process — not so, since Kwik-Print wasn’t based upon pigments — likely they were inksets. No patent was ever filed for the process in any of its trademarked forms; neither by Direct Reproductions, nor Light Impressions.

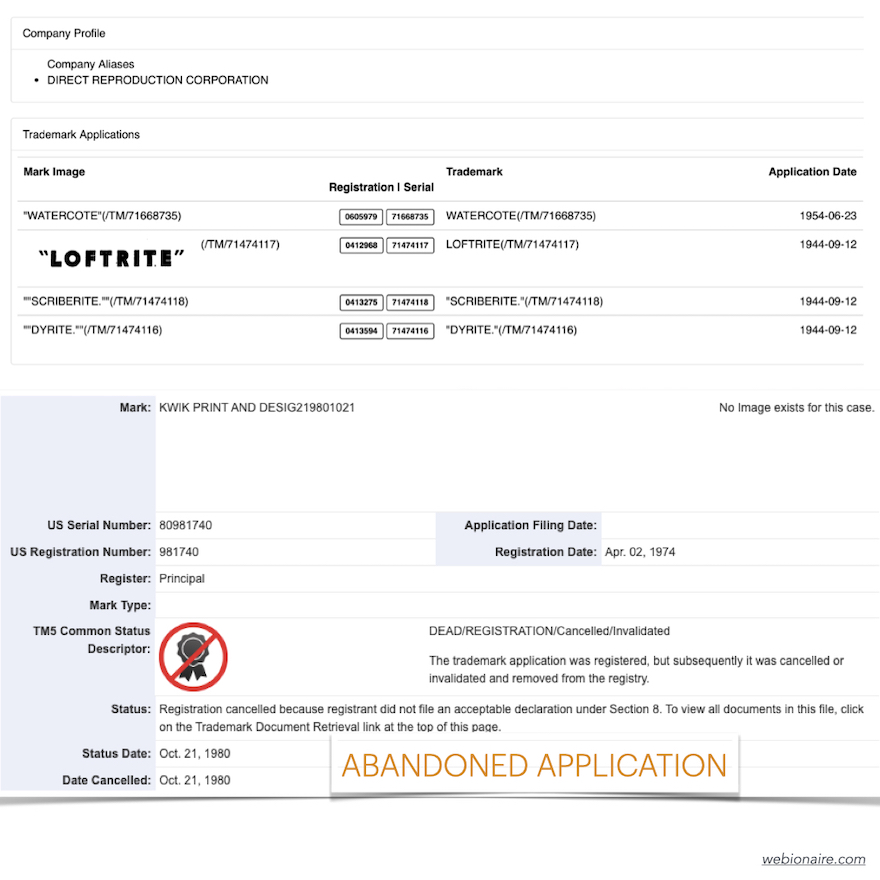

The process was not patented. The product trademarks were the only protection for Direct Reproduction Corps. small business.

kwik proof by Samuel Sacks 1941

A telltale aspect of the kwi-Print was the synthetic “paper” support used. It was easier than similar processes such as gum-arabic, since the emulsion came ready to use; no grinding, no mixing. Synthetic wipes were used to apply coating to the synthetic paper which dried quickly without shrinkage. A multicolor print could be completed in minutes rather than hours as with gum prints.

Contrast of sheets: the receiver sheets affected contrast of the image; they were offered in three distinct grades of contrast. These sheets had code-notches to mark them, however, since the contrast change was due to the surface sheen/ diffusion (see callier) examining the sheet by raked light told which was high or low contrast — how shiny did it seem; how smooth did it feel.

So, why read about it? Sometimes the past reveals a future. Procedures change, shift, die — theory never dies, it transforms.

a short time on photography’s craft stage. it was part of the alternative life phase of Rochester’s boom years. Taking part in the silver-rush seventies by adding color without Kodak and friends.

How processes take hold; what it took for Kwik-Print.

- It must be simple enough to learn within a short time such as a workshop

- It is stronger if introduced in a time of growth among the arts community — the 70s was the explosion of photography into art schools.

- It needs an advocate able to say, do and show what and how the process fits into that time

- It helps if there is a strong commercial need of the process. Kwik-Proof was re-badged from the commercial printing trade where it was used for several decades. At the time of its conversion to the fine-art, solo studio practitioner, it was falling from use.

Before Post-Factory was alt=photography. Before that was non-silver imaging.

Bea Nettles was the proponent of the Kwik-Print stage of pigment printing. It was sold as kit and as individual items. Kwik-Print was a modification of the Kwik-Proof graphic arts product originated and sold by Direct Reproductions Corporation, Brooklyn,N.Y. The colorants used were not designed for permanence under display conditions. Keep em covered.

Light Impressions, 131 Gould Street, Rochester, NY was the large scale supplier to the fine-art photographers, ie, those educated in the art schools that seemed endless during the growth of gallery photography.

Some of the who:

bea nettles (b.1946 -) — a key advocate. She brought the Direct Reproduction Corporation product to the handmade emulsion community via Light Impressions.

- charles & elizabeth swedlund [b.1935 ] — https://www.artic.edu/artists/36853/charles-swedlund

- arnold gassan [b.1930 ] — https://www.artic.edu/artists/9336/arnold-gassan

- david scopick — [b. 1948 – 2024, (76)] — https://www.ocadu.ca/news/ocad-u-mourns-passing-former-faculty-member-david-scopick

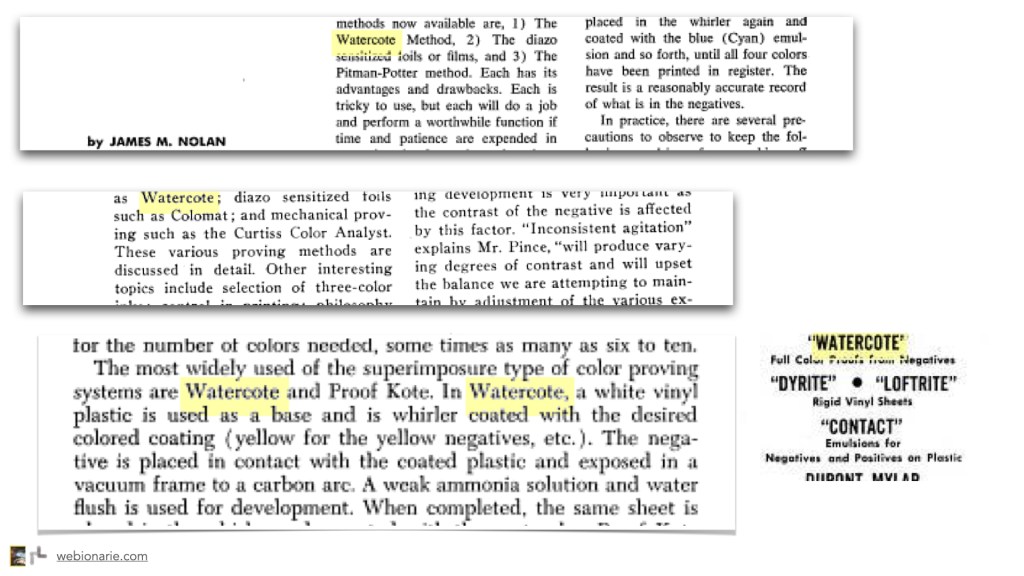

watercote: The American Photo Engraver, Volume 49, 1957

The trademarks for Kwik-Proof, along with the unfinished application for Kwik-Print.

Knowing where to look comes before finding.

Interested about the past? A common first thought is ask the web. As part of a continuing task of checking cultural progress, I asked 4 published bots. My request and the response follow:

The internet past is restricted to the 21st century. The printed page was not digitized. Try asking a librarian for the information. Librarians at large research libraries have extensive resources.

My first searches are to my bookshelves, then to online known reference sites.

Never ask a passing bot; never ask a hobby spot, even if this is “just” a hobby.

You must be logged in to post a comment.