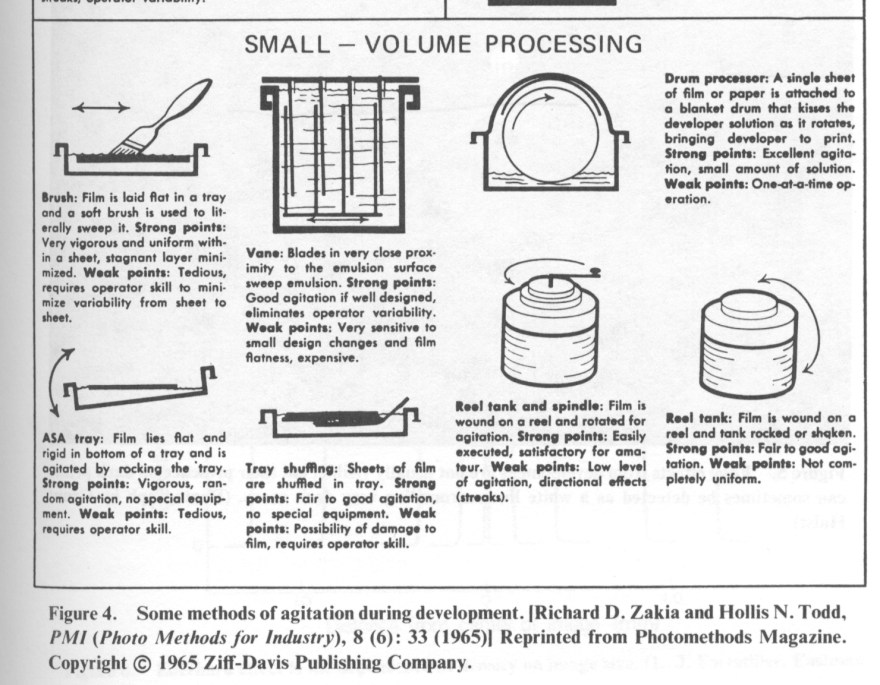

kinetics. induction period. specific agent, ex: phenidone [mees, 1969]. Chemical processing is a mechanical process. Rates and timing of agitation, of exchanging chemistry across the image will alter the shape of the characteristic curve. [I have curves showing the effects; pondering their posting]

Agitation is one of the two commonly misplaced skills of developing. The other is water– purity and bubbles.

Many of the early errors are errors of judgement, then of mechanics. You are using too little chemistry, relying upon equipment designed to save chemistry as it provides ready salvation of all your space limitations. This makes the task of getting the film fully saturated with chemistry and chemistry only more difficult. Success is requires the film is evenly wet and equally swollen evenly and quickly. Immersion of the film into the chems, coupled with agitation during this stage will solve the first dozen errors of processing your film.

I learned by adage; this one was from processing in dye transfer labs: “Mix for four, use three” — meaning mix enough chems to process 4 sheets of film, but only put 3 sheets through the chems.

i can’t convince you that what you do doesn’t work, although most descriptions of action seem to hold to an error, so your modification is a correction of your error — at times, these errors are because of the equipment , not your usage, more often the mistake is a result of agitation of the processing chemistry.

What does wetting the emulsion before developing do, achieve? Is it essential or chicken bones in the campfire. I have pre-soaked as an experiment. I don’t presoak for my work, nor for any commercial client. I don’t use water with “bubbles” in it; let it stand before adding other chemicals, even when diluting stock chemicals.

I modify the tanks used in souping rollfilm by sticking silicon bumpers to the inside bottom of the tank;this modification provides space for chemicals to flow across the bottom of the reel.

Chemistry must surround the emulsion for even processing. The critical image former is developer — the latent image must be amplified by chemical means.

Laminar flow was implemented in a small scale way for the home color print market by Agnecolor [*]

[spiral ribs wash more of surface without ‘tracks’ of trapped chems. — print drums]

How long does an emulsion have to be wet before achieving maximum swell? The emulsion isn’t fully expanded until washing. Notice that it shrinks in fixer. Water keeps the emulsion swollen. The following illustration tracks this over time and at three different temperatures. It was conducted as part of research on emulsion hardening and need for supplementary harderners. Some emulsionists devised wetting agents and antifoam additions to film to address the problems of widely different water conditions their product would encounter in the wild.

Pre-soak. Pre-wet. Ilford or Kodak. Tray, tank, burst, reels. Air bells. Pinholes. Uneven development. Pyro in the sky with Jobos.

Dye Transfer as learning lab

Masks, separations, matrix film: ortho, or pan each has such difference that an experiment, once run, wasn’t run more often. Making masks, in various forms, on variety of film types, would seem to be a great circumstance to realize any gains in pre-soak. Short development time, required evenness of tone-sets, avoiding any processor defect, all these seem prompt for initial wetting. I didn’t know about it when I started, and in none of the labs where I first worked was it used. Of course, none of these places used Jobos, or other “can and roll” processing modes.

One client funded researching pre-soaking matrix film. They wanted to process mats in daylight drums purposed from color RC processing. They hoped to be able to load pan-matrix film in exposure cube, then process in a larger wetroom. We achieved some success, enough that the client was happy to hire me again. The method required presoaking the Pan Matrix film in an antifog / restrainer solution. Loading the drum with “knurled rubber fingers” — time in this mix was 4 minutes, followed by a rinse in distilled water, finally the matrix developer for much lengthened processing time.

I never used the procedure in my work, nor did I teach it to any other lab.

Does an expert have expertise in all things? Clearly not. Does an expert in the field have expertise across the entirety of use? Only if they phrase their answer specifically to a question rather than the entire topic possible. So, does” pre-soaking harm BW emulsions” is different than “is pre-saoking necessary to maximize results” — In my experience evolution from a self-informed dye transfer maker in 1960 to now, 2024, I have gained enough observation to know that agitation systems have more effect than almost any other part of what the user of emulsions does. Agitation is amplification; it is limited, and so must be altered to mate material and mechanism — a Jobo has limitations. As does a tray, a shallow tank, or burst system. I have never used a Jobo, although a Merz featured prominently in two different labs I managed.

Tray AGITATION. plating shuffle. wet hand, dry hand. having a start sheet-code with many. depth of liquid — more is better.

PRE-SOAK– solves wetting because too little chem, and-or too little agitation at developer induction — the physical part of film getting wet. water is the ‘universal solvent’ in photography — color emulsions have development modifiers within their layers; these activate, diluted, they don’t act as designed as part of ’emulsion + developer’ system.

if tray processing film sticks, you aren’t using enough time (10 or 15 second) steps between sheets in the stack. most people use too shallow a chem for the stack, also, they put them into the dev too rapid a sequence.

i usually used a scavenger sheet of film on the bottom of the tray.

Additional on processing drum systems:

Read these patents, then estimate the contribution made by Jobo.

You must be logged in to post a comment.